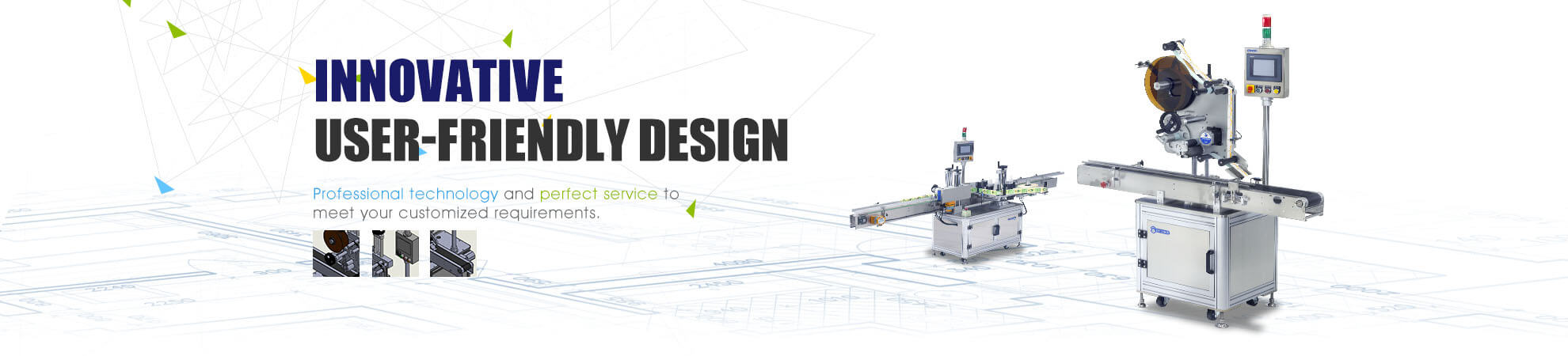

Research&Development

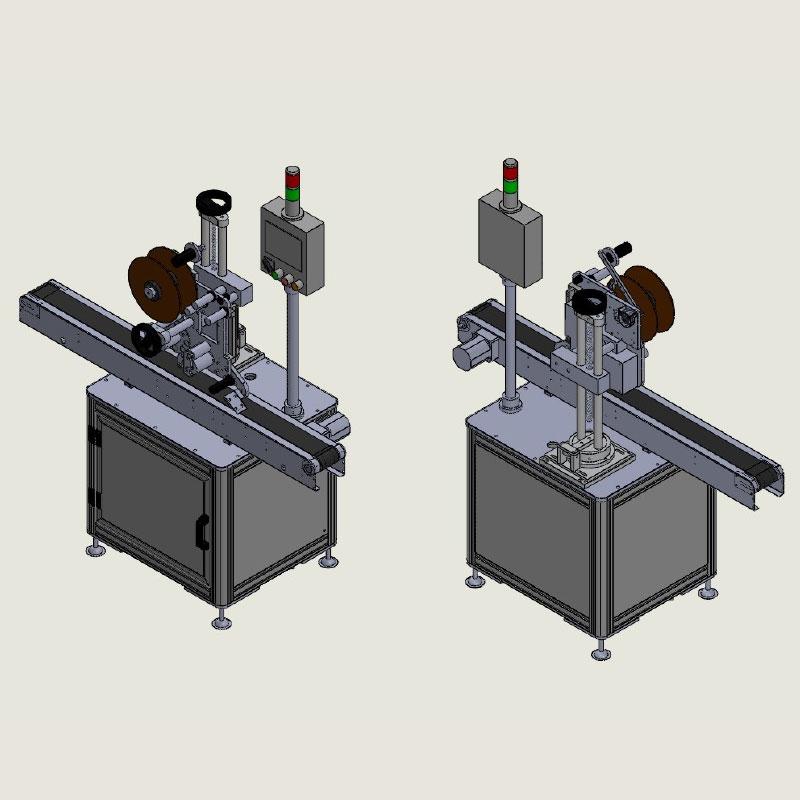

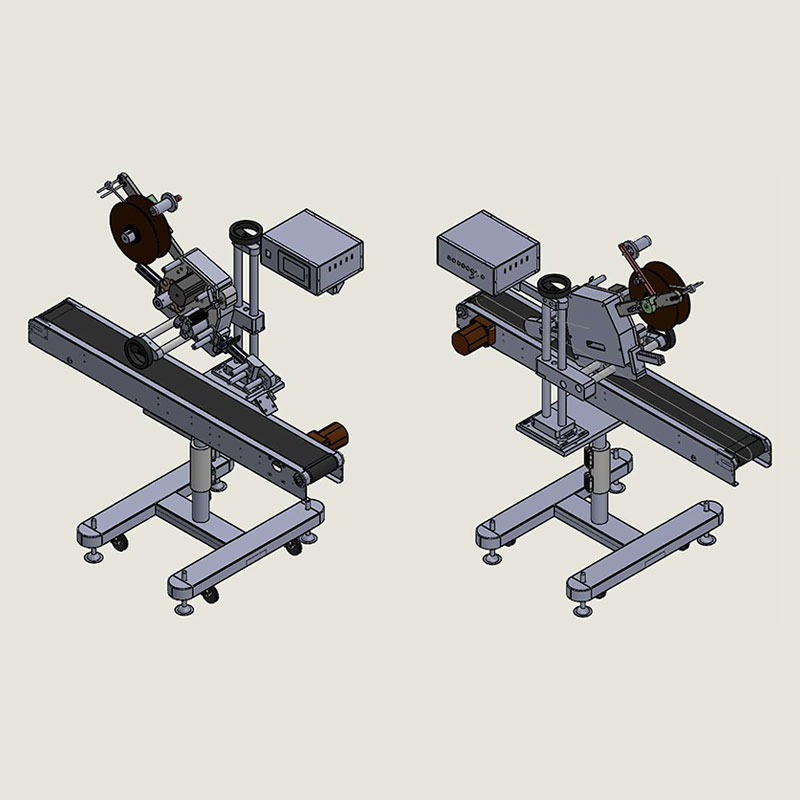

In the early stage, the automatic labeling machine prints the label of whole volume, which attaches labels on the product separately to save manpower resources. However, we had enhanced the automatic labeling machine in recent years, which can print product code on the merchandise directly. In this way, we make stores checkout more effectively. In recent years, Taiwan has been facing the problem of global low birthrate, industrial manufacturing 3.0 upgraded to industrial intelligence 4.0. To comfort the trend, ARTPACK upgrades the automatic labeling machine to meet the intelligent development, which is from automatic feeding mechanism to replace the artificial feeding. Also we install sensory eyes to check if the labels leak or skew automatically after the label attached to the goods.

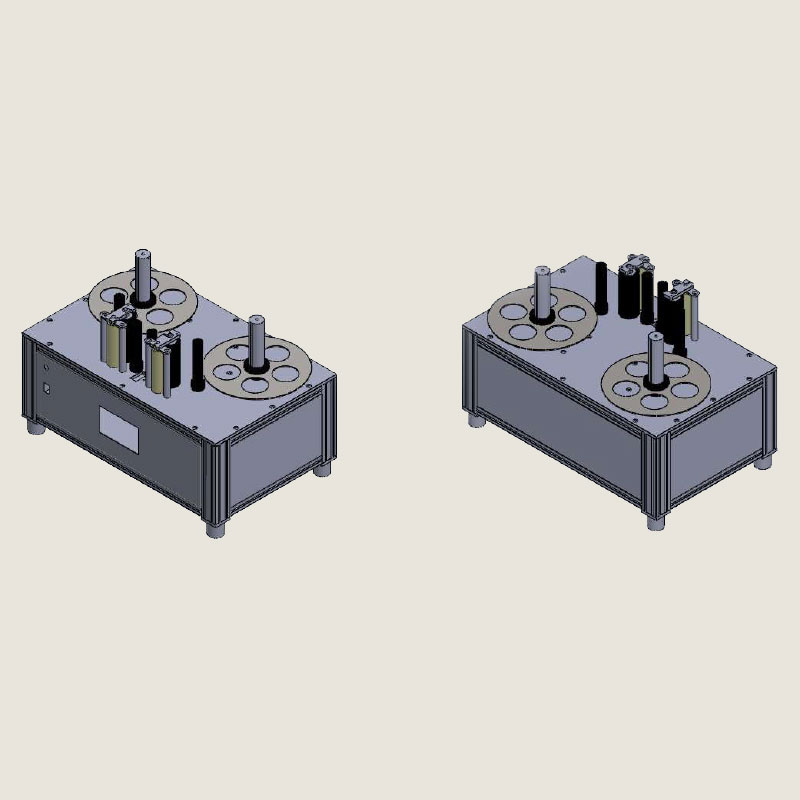

In order to improve your productivity, ARTPACK make machines stack columns into a box, and then attach a two-dimensional code label on outer box scanned by CCD. By this way, the code will be read instantly by the PC, and be warehousing automatically by your system.

All in all, the ultimate goal of ARTPACK is to provide intelligent benefits on manufacturing 4.0 , and maximize the efficacy.

.jpg)

.jpg)

.jpg)